OBJECTIVES:

- COB1: To impart knowledge on the structure, properties, phase diagrams and applications of materials so as to identify and select suitable materials for various engineering applications.

- COB2: To study about the structure, properties and applications of various materials like ferrous, non-ferrous and its alloys.

- COB3: To give insight in to non-metallic materials such as polymers, ceramics and composites.

- COB4: Impart the students to investigate, analyze and provide solutions using heat treatment process and strengthening mechanism.

- COB5: To develop knowledge on the mechanical properties of materials through various testing procedures in engineering field.

OUTCOMES:

On completion of the course the students should be able to:

- CO1:identify various phases of metals and alloys through appropriate phase diagrams, describe the structure of materials, defects and suggest suitable engineering materials for different application

- CO2:evaluate the effect of alloying elements, properties and application of ferrous and non-ferrous metals

- CO3:apply advanced materials such as polymers, ceramics and composites in product design

- CO4:select and apply appropriate heat treatmentprocess and strengthening mechanisms to modify the mechanical behaviour of various materials

- CO5:Evaluate the mechanical behavior of materials for different applications

COURSE CONTENT

MODULE I - CRYSTALLOGRAPHY, CONSITITUTION OF METAL AND METAL ALLOYS

Fundamentals, Crystal structure – Types, Crystal imperfections, Grain size,

Constitution of alloys, Lever Rule, Solid solutions-substitutional and interstitial.

Phase diagrams - Isomorphous, eutectic, peritectic, eutectoid and peritectoid

reactions, Iron – Iron carbide equilibrium diagram, Development of

Microstructure in Iron–Carbon Alloys.

MODULE II - FERROUS AND NON FERROUS METALS

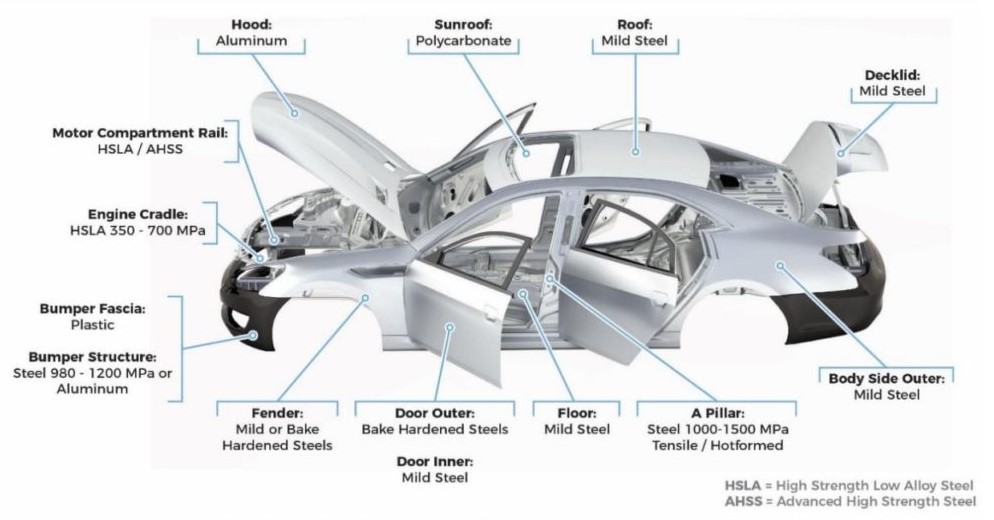

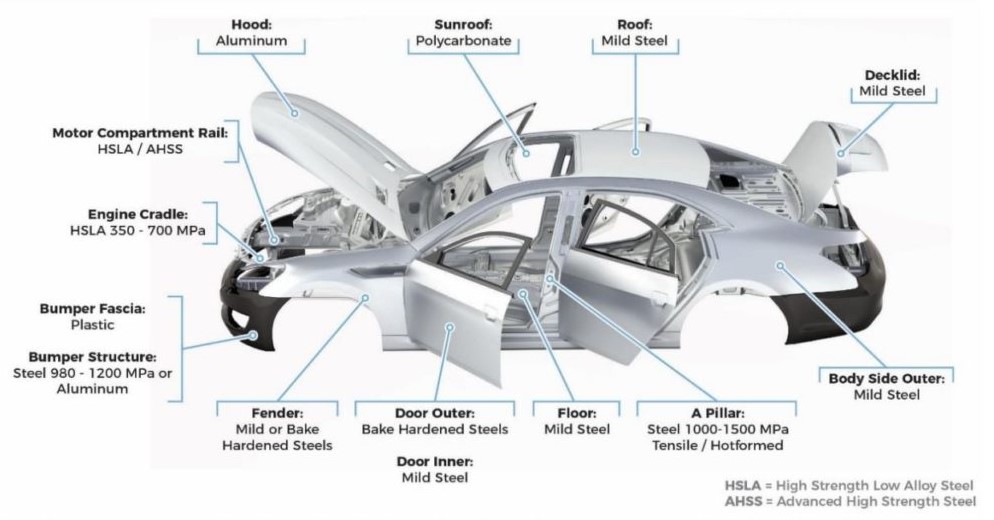

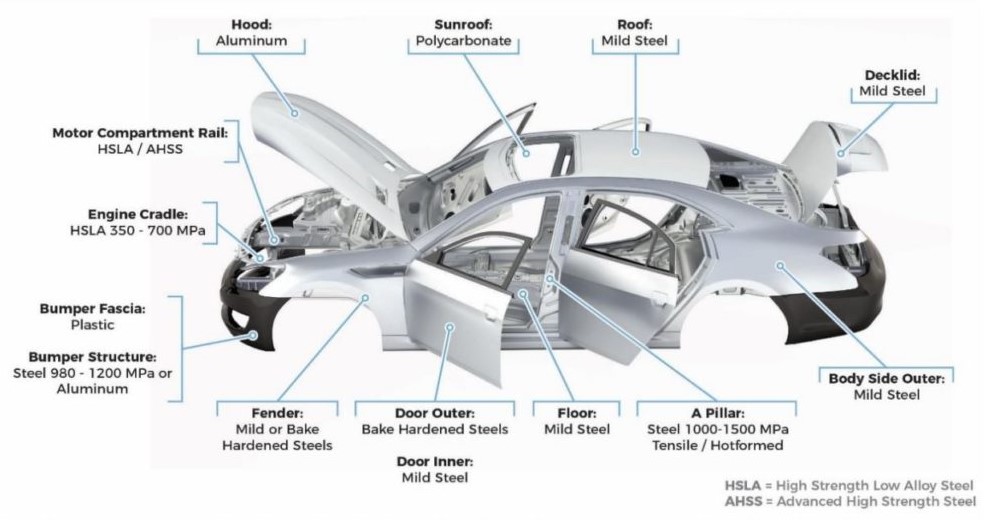

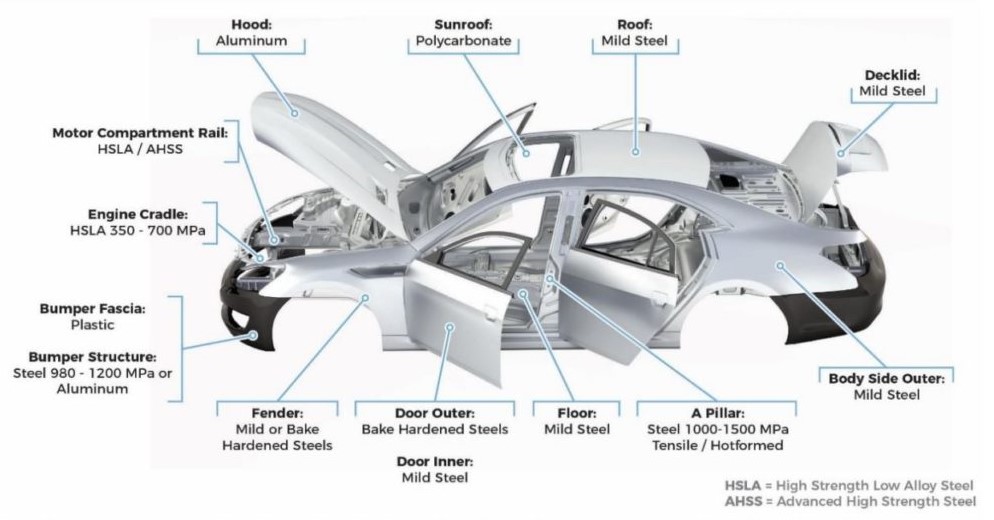

Plain carbon steel and cast iron – classification, microstructure, properties and applications. Effect of alloying additions on steel (Mn, Si, Cr, Mo, V Ti & W). Stainless steel, tool steels, HSLA and Maraging steel - properties and applications, Copper and its alloys. Aluminium and its alloys, Magnesium and its alloys, Titanium and its alloys – microstructure, properties and applications.

MODULE III - NON-METALLIC MATERIALS

Properties and Applications of various Engineering Polymers, Properties and

applications of various Ceramics, Composites and their types, properties and

applications

MODULE IV - HEAT TREATMENT AND STRENGTHENING MECHANISMS

Fundamentals, Classification of processes - Full annealing, normalizing,

Hardening and tempering of steel. Isothermal transformation diagrams,

Continuous Cooling Transformation Diagrams. Case hardening processes -

carburising, nitriding, cyaniding, carbo nitriding, Flame and Induction

hardening. Grain size strengthening, Solid solution strengthening, strain

hardening, yield point phenomenon, dispersion strengthening, fibre

strengthening, precipitation strengthening.

MODULE V - MECHANICAL PROPERTIES AND TESTING

Mechanism of plastic deformation, slip and twinning, types of fracture. Testing

of materials: ASTM standards, Metallographic Examination, Hardness tests,

Impact test Tension test, Wear test, Fatigue test and Creep test.